Washers may seem small and insignificant, but they are important. The reason you need washers when working with threaded fasteners goes beyond just stability – it's about ensuring long-lasting connections.

In this article, we will explore how to use washers with screws effectively, when they are needed, and their importance in creating a durable seal with gaskets.

What Is a Washer?

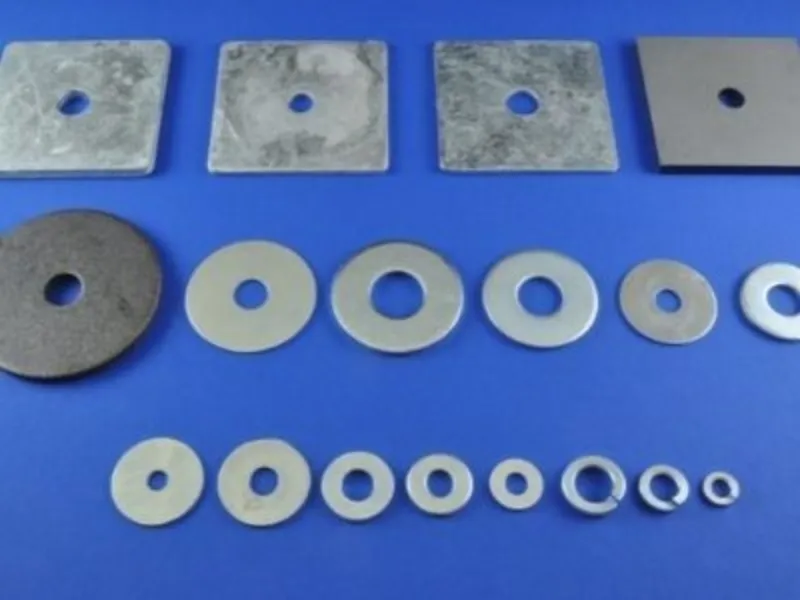

Washers are flat, thin rings or perforated plates that are used in joints or assemblies. They serve important functions, such as ensuring tightness, preventing leakage, and reducing friction. Typically, washers are used with screws or bolts to distribute the load and protect the surface being fastened.

A washer helps to minimize the risk of the fastener becoming loose over time due to vibration or temperature changes. Washers can be made from various materials, including metal and plastic, and are available in different sizes to suit different applications.

Why Are Washers Necessary?

When used with a screw, a washer can prevent damage to the joint's bearing surface that could occur when the screw threads dig into the material during tightening.

Washers distribute the load, which is particularly vital when driving into soft materials such as wood or aluminum, which are vulnerable to stress-related damage. This resistance to stress not only prevents damage, but also counteracts movement and corrosion.

Types of Washers and Their Applications

Flat Washers

Flat washers provide a smooth surface between the screw or bolt head and the material being fastened, to distribute the load evenly while preventing damage to the hole and ensuring secure fastening. Flat washers are used for most general applications.

Split Lock Washers

Split lock washers are used in high-vibration environments, where the concern of loosening a threaded fastener is present. They have a split design that increases friction when tightened, to reduce the likelihood of screws or bolts coming loose.

Belleville Washers

Also known as spring washers, Belleville washers are widely used in the aerospace, oil and gas, and automotive industries. They offer unique properties with their spring-like tension, which makes them ideal for applications that require controlled compression and constant pressure.

They are commonly used in conjunction with threaded fasteners such as bolts and nuts to provide a reliable bearing surface. Their ability to handle challenging conditions makes them a popular choice in various industries.

Fender Washers

For situations requiring weight distribution over a larger area or added stability, fender washers are an excellent choice. Their larger outer diameter helps distribute weight more evenly, to help prevent sinking or damage to the material. Construction, plumbing, and outdoor applications commonly benefit from the use of fender washers, as they provide added support when used with threaded fasteners such as bolts and nuts.

Tab Washers

Aerospace and medical applications often use tab washers, either as a type of lock washer or a standalone option. Tab washers are known for their resistance to extreme heat conditions and heavy vibrations.

Bonded Neoprene Washers

Bonded neoprene washers are a type of washer made from neoprene rubber that has been bonded or adhered to a metal or plastic backing. Neoprene rubber is a synthetic rubber known for its excellent resistance to oil, ozone, weathering, and abrasion, which makes it a popular choice for various sealing and cushioning applications.

They are commonly used in applications where a watertight seal is required, such as plumbing fittings, faucet connections, and water supply lines. The neoprene rubber helps to prevent leaks by creating a tight seal between the mating surfaces.

Shoulder Washers

Used primarily in electronics, shoulder washers provide heat and electrical insulation to fasteners or shafts within electronic equipment.

Finishing Washers

Aesthetically pleasing finishing washers are frequently used in furniture and freshwater marine applications. They allow flat or oval head countersunk screws to be installed flush with the part’s bearing surface.

Proper Installation of Washers on Screws

To ensure the proper installation of washers on threaded fasteners like screws and bolts, it is essential to follow a few key steps. By doing so, you can maximize the effectiveness and functionality of your fastening system:

- Match Washer Size to Screw Size: Always ensure that the washer size matches the screw size. This ensures a proper fit and prevents any potential issues down the line.

- Placement Matters: Place the washer directly under the screw head or nut. This positioning maximizes its effectiveness by evenly distributing pressure to help prevent damage to the underlying material.

- Tighten Gradually and Evenly: When tightening screws, it's crucial to do so gradually and evenly. Avoid rushing or applying excessive force as this may damage the washer or distort its shape.

- Use Appropriate Tools: To achieve optimal tightening without overloading or stripping threads, use a torque wrench or suitable tool for your specific application. This ensures consistent results and avoids unnecessary complications.

The Importance of Washers in Gasket Sealing

Washers are vital in maintaining the integrity of gasket seals. When tightened, the screws and washers apply uniform pressure to the gasket, to help ensure a tight seal that prevents leaks. If the screw is directly tightened onto the gasket without a washer, it could lead to uneven pressure distribution and compromise the seal.

Rely on Fastener Systems for Reliable, Durable Washer and Screw Solutions

The right use of washers with screws can significantly enhance the life and performance of your assembly. At Fastener Systems Inc., we offer a wide range of washers for different applications, to help ensure that your assembly is done correctly and efficiently. Don't know which washer to use with your screws? Our experts are always ready to advise you.

Contact us today for all your fastening needs!