Constructing a long-lasting, attractive deck that endures through time begins by selecting the appropriate fasteners. With numerous choices out there, it might feel overwhelming to find the ideal screws for treated lumber and composite decks.

This article seeks to clarify the process by equipping you with the information necessary to make a well-informed choice.

Understanding the Essentials of Deck Building

Understanding the essentials of deck building hinges on selecting the right materials and fasteners. The durability and safety of your deck depend on using screws that are designed to cope with the specific challenges of pressure-treated wood and composite materials. These materials require fasteners that can resist corrosion from chemicals and withstand outdoor conditions.

The right screws ensure that your deck remains secure and maintains its appearance over time, which makes the choice of materials and fasteners a critical step in the deck-building process.

Selecting the Best Screws for Pressure-Treated Wood and Composite Decks

Choosing Screws for Pressure-Treated Wood

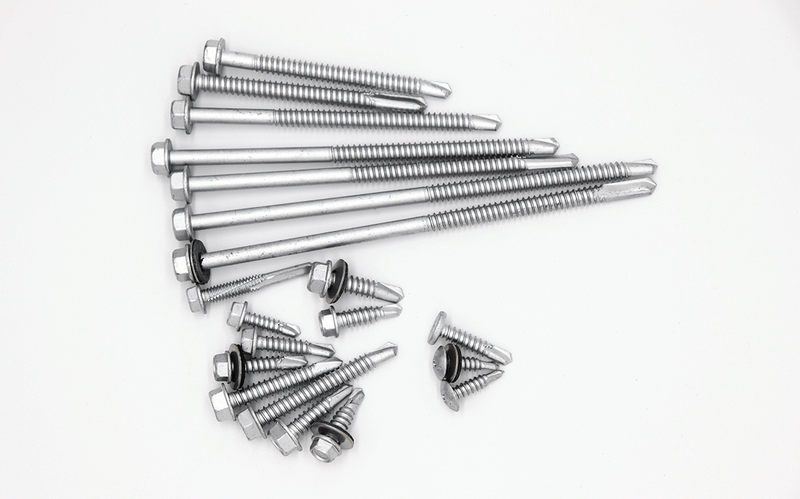

Pressure-treated lumber is treated with chemicals to resist rot, decay, and termites. However, these chemicals can corrode standard fasteners, which makes corrosion resistance a critical factor in screw selection. Stainless steel and polymer-coated screws offer the protection needed to ensure your deck's longevity.

Selecting Screws for Composite Decks

Composite decking materials are prized for their durability and ease of maintenance but require specific screws to prevent issues like mushrooming, where the material bulks up around the screw head, and splitting. Composite deck screws and trim head screws are designed to address these concerns, to provide a clean finish and strong hold.

Coatings and Materials: Maximizing Durability and Performance

The longevity of your deck hinges on the ability of your screws to resist corrosion.

- High-quality polymer coatings and stainless steel materials stand at the forefront of protection against the harsh chemicals in pressure-treated lumber and environmental elements.

- Select screws with advanced coatings for enhanced durability and consider the environment of your deck project when choosing between 304, 305, or 316 stainless steel grades.

By focusing on these key factors, you can ensure your deck remains strong and beautiful for years to come.

Drive Types and Thread Design: Ensuring a Secure Fit

When it comes to building a deck that's both durable and visually appealing, the devil is truly in the details—specifically, the type of screws you choose. Drive types and thread design play pivotal roles in the overall success of your deck construction by impacting everything from the ease of installation to the longevity of the materials.

Drive Types: Beyond the Basics

The choice between square, Torx (star), and traditional Philips or Bugle heads may seem small, but it greatly impacts how smoothly your deck-building project goes.

Square and Torx drives provide better bit engagement than Philips and Bugle, which lowers the chance of stripping during installation. This advantage makes them easier to use and ensures a stronger fit, which is vital for your deck's structural integrity.

Thread Design: Cutting-Edge Innovations

Recent advances in thread design have revolutionized deck construction, specifically addressing common issues like wood splitting and the unattractive "mushrooming" effect in composite materials.

- Self-starting cut points are a notable innovation that reduces wood splitting and ensures a smoother installation process.

- Dual-threaded screws are another breakthrough that offers a tighter connection between deck boards and joists, which not only strengthens the structure, but also improves its aesthetic by ensuring a flush finish.

- For composite decks, screws with reverse threads combat mushrooming by effectively removing excess material for a clean look.

These developments in screw technology simplify the construction process and contribute to the durability and visual appeal of the finished deck.

Installation Tips for Optimal Performance

Proper installation techniques are crucial for both pressure-treated wood and composite decking to ensure the longevity and stability of your deck. Here are detailed tips for each material type, distinguished by their specific requirements and considerations.

For Pressure-Treated Wood

Pre-Drill to Prevent Splitting

Always pre-drill holes when working with pressure-treated wood, which can be dense and prone to splitting. This step helps to prevent damage to the wood and ensures screws can be driven smoothly.

Use the Correct Screw Type

Opt for screws specifically designed for pressure-treated wood, which will be resistant to the chemicals used in the wood and capable of withstanding environmental exposure without corroding.

Follow Manufacturer Guidelines for Bit Size and Screw Length

Making sure that you use the recommended bit size and appropriate screw length for the thickness of your decking material is key to securing the deck properly without compromising the wood's integrity.

For Composite Decking

Select Composite Deck-Specific Screws

These screws are tailored to address common issues with composite materials, such as mushrooming, and often come with a reverse thread design to pull the decking tightly against the joist and provide a clean finish.

Accommodate Expansion and Contraction

Leave appropriate spacing between boards and adjacent structures to allow for the expansion and contraction of composite materials with temperature changes. This prevents warping and maintains the aesthetics of your deck.

Consult Manufacturer's Installation Guidelines

Composite decking brands may have specific installation instructions, including spacing requirements and fastener types. Adhering to these guidelines not only ensures optimal performance, it also preserves the product warranty.

Your Ideal Deck Starts with the Right Screws from Fastener Systems

Fastener Systems Inc. (FSI) is your go-to source for high-quality fasteners and screws for pressure-treated wood and composite deck projects. Our extensive range of screws is designed to provide the strength, durability, and aesthetic appeal your decking projects require. We invite you to explore our selection and leverage our expertise to find the perfect fasteners for your next project.

Contact us today for more information!