Considering spray foam insulation or fiberglass insulation for your home or business? Weighing their advantages and drawbacks is essential in helping you make the best decision. This article dives into a comprehensive comparison of both types so that you can make an educated choice about which solution works for your budget and R-value needs!

What is Spray Foam Insulation?

Spray foam insulation consists of two main components: polyurethane and inert gas, usually air or nitrogen. When these two components are mixed, they expand rapidly into a foam-like material that can fill any cracks or crevices in the surface being insulated. The foam then expands and hardens to create a barrier against heat loss or gain.

Spray foam insulation can be applied to walls, ceilings, floors, and even around pipes and ductwork to create an air-tight seal. There are two types of spray foam insulation: open-cell and closed-cell.

Open Cell

Open cell foam is a rubber-like material made with an inflating agent, such as baking soda. The chemicals react to heat during the vulcanization process and form tiny pockets of gas bubbles that cause the foam to spread out into its signature open-cellular structure.

Closed Cell

Closed-cell spray foam insulation is a type of insulation that is made up of tiny cells filled with gas. It is a type of polyurethane foam that is sprayed onto surfaces to provide an airtight seal and insulation. Closed-cell spray foam has a higher R-value than open-cell, which results in superior thermal insulation and energy efficiency.

It also helps reduce noise levels, so it is ideal for soundproofing applications. Additionally, closed-cell spray foam has superior water resistance, which makes it great for areas prone to moisture or flooding.

What is Fiberglass Insulation?

Fiberglass insulation is made from tiny glass fibers spun together into a mat-like material. It’s typically used in attics and walls to provide thermal protection against heat loss or gain. While fiberglass insulation does provide some protection, it's not as effective as spray foam; the latter creates an impenetrable barrier that prevents air from entering or escaping.

However, it does provide good soundproofing qualities and can be installed relatively quickly and easily compared to spray foam insulation. It also tends to be less expensive than spray foam insulation per square foot, installed.

Types of Fiberglass Insulation

Batts

Batt insulation is the perfect choice for construction projects because it effectively muffles noise and keeps temperatures regulated. This type of insulation, constructed from fiberglass or rock wool, comes in pre-cut sheets or rolls that are designed to fit into cavities between wooden framing pieces within walls, floors, and ceilings. Batt insulation is available in either faced or unfaced varieties.

Faced Fiberglass Batt Insulation

Faced batt insulation is a type of insulation made from fiberglass, which helps to regulate the temperature in your home. It is composed of small fibers that are held together by a paper or plastic facing known as a vapor retarder. The facing helps to prevent moisture from accumulating between exterior walls and floors, thus reducing the risk of mold and mildew growth.

Unfaced Fiberglass Batt Insulation

Unfaced insulation is an ideal solution for new construction, home renovations, walls, floors, ceilings, and basements. It is best used in areas that don't face the outdoors or require moisture control; living rooms, dining rooms, and studies! Attics and crawl spaces also benefit from unfaced insulation.

Loose fill/Blown-in Insulation

Loose fill or blown-in insulation is an effective way to insulate your home. It is made up of small particles of fiber, foam, or other materials that are blown into the space to be insulated. This type of insulation can conform to irregularly shaped spaces and provide a great deal of coverage for your home while providing an R-value of 2.2 to 2.7 per inch of thickness. Loose-fill insulation comes in two main varieties: cellulose and fiberglass.

Cellulose takes more material to insulate the same area than fiberglass, but it offers superior performance in terms of energy efficiency and soundproofing.

Comparing Spray Foam vs. Fiberglass Insulation

When comparing spray foam vs fiberglass insulation, several factors need to be taken into consideration including cost, installation ease, R-value (thermal resistance), soundproofing capabilities, fire resistance properties, and environmental impact.

Cost

Closed-cell spray foam is usually the most expensive of all options at approximately $1.50 -$3 per square foot. Open-cell spray foam offers mid-range pricing around $0.50 -$1.50 per sq ft. Fiberglass insulation tends to be cheaper in comparison, averaging $.0.10 - $0.50 per sq ft.

Installation Ease

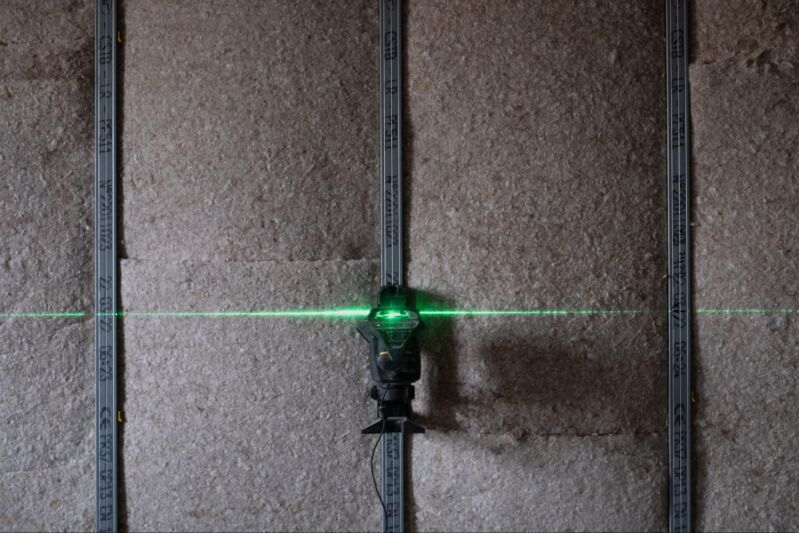

Installing spray foam requires specialized equipment and training which makes it more time-consuming than installing fiberglass insulation; however, its ability to fill small cracks and crevices makes it ideal for hard-to-reach areas where traditional materials may not fit properly or securely enough for effective thermal protection against heat transfer.

Fiberglass, on the other hand, requires less specialized equipment but may require additional cutting/shaping if being used in areas with irregular shapes or sizes such as around pipes or wiring systems which could add additional time/costs associated with installation services depending on the specific project requirements.

R-Value

The R-value measures the thermal resistance of an insulating material. The higher the R-value number, the better the thermal protection against heat transfer from outside sources into your home/business environment (or vice versa). Spray foam has a higher R-value rating than fiberglass that makes it more effective at preventing heat transfer from inside or outside.

Soundproofing Capabilities

Both spray foam and fiberglass offer some soundproofing capabilities; however due to its airtight seal created when sprayed onto surfaces spray foam provides superior soundproofing qualities compared to traditional materials like fiberglass which do not create an airtight seal when installed, thus allowing some noise transmission through walls/ceilings etc.

Fire Resistance Properties

Both types of insulation have some fire resistance properties. However, due to its chemical composition when exposed directly to flames, spray foam may burn if not treated to resist fire. Traditional materials like fiberglass and mineral wool will not ignite when exposed directly to flames, which makes them safer options in terms of fire safety.

Fastener Systems, Inc. Carries Environmentally-Friendly DuPont Spray Foam Products

FSI carries DuPont FROTH-PAK™ closed-cell spray foam kits.

Foam insulation is an ideal, one-stop solution for professional contractors and DIYers as well. It's portable and easy to use - so that you can quickly fill larger gaps, such as those found in metal building construction. Unlike traditional spray foam insulation, Froth-Paks are pollution free and contain no ozone-depleting chemicals or HFCs; yet still offer exceptional performance benefits you can depend on.

Contact us today for more information on our spray foam insulation equipment and order a catalog to view our complete line of fasteners and tools.