Screws are one of the most reliable and versatile types of fasteners available, with countless applications across a variety of industries. From drywall screws for hanging pictures to self-drilling screws for metal construction, there is a type of screw perfectly suited to every job. In this article, we will explore the variety of options available when it comes to screw selection and what each type is intended for.

What Are the Basic Parts of a Screw?

A screw is a type of mechanical fastener that is typically comprised of three main parts: the head, the shank, and the threads. The head is the top part of the screw, which provides a surface for tools to grip and apply torque during installation or removal.

Screw heads come in various shapes and sizes, such as flat, round, pan, hex, and many others. The choice of head style depends on the specific application and the desired aesthetic or functional result.

The shank is the long, cylindrical part of the screw that extends from the head to the tip. It can be fully threaded or partially threaded, depending on the intended use.

The threads are the helical grooves that wrap around the shank and provide the screw with its characteristic ability to grip and secure materials. Depending on the material, the threads may be coarse or fine. Coarse threads are better suited for softer materials such as wood, while finer threads are more appropriate for harder substances like metal.

The tip of the screw can also vary, with some screws having a sharp, self-drilling point that eliminates the need for pre-drilling pilot holes, while others require a pre-drilled hole to ensure proper installation.

14 Different Types of Screws and Their Uses

1. Wood Screws

Wood screws are a type of fastener used to join two pieces of wood together. They are designed with large threads that cut into the wood to provide a strong and secure connection. Unlike nails, wood screws may require a pilot hole for installation.

The most common type of wood screw is the Phillips drive, which has an X-shaped head that allows it to be installed with a Phillips screwdriver.

Hardwood screws typically have tighter threads than softwoods, which means more threads per inch. This helps prevent splitting when installing into hardwoods.

2. Machine Screws

Machine screws are a type of fastener that differ from other screws in that they do not drill through materials themselves. Instead, they are used in conjunction with pre-drilled and tapped holes, which have threads cut into them to accommodate the machine screw. When a machine screw is inserted into a tapped hole and secured with a nut, the resulting tension causes the screw to stretch, which forms a strong and stable bond.

Machine screws are commonly used in situations where precision and strength are required, such as in the assembly of machinery, electronics, appliances, and vehicles.

3. Sheet Metal Screws

Sheet metal screws are specialized fasteners designed for connecting thin metal sheets or other materials like plastic, wood, and aluminum. They are categorized by their head styles and three numerical values that represent the screw's diameter, length, and thread count. The diameter, which refers to the size of the screw's shank, is indicated by a number between zero and 24, with the most common sizes ranging from 6 to 14.

4. Drywall Screws

Drywall screws are specifically created to install drywall panels. Drywall screws have bugle heads that protect against tearing the paper surface as well as a sharp point for easy penetration. You can find them with either coarse threads suited for wood studs or fine threads made specifically for metal studs.

5. Concrete Screws

Concrete screws, also known as masonry screws, are designed to fasten materials to concrete, brick, and block. They have a high-low thread design that allows for easy installation and strong holding power. Concrete screws typically have a hex, bugle or flat head and require a pre-drilled hole for proper installation.

6. Deck Screws

Deck screws are specifically designed for outdoor wood applications, such as decking, fencing, and railing. They are made from corrosion-resistant materials like stainless steel, and their specialized design helps to prevent wood splitting. Deck screws have a bugle head, which allows for flush installation, and a sharp point for easy penetration into the wood.

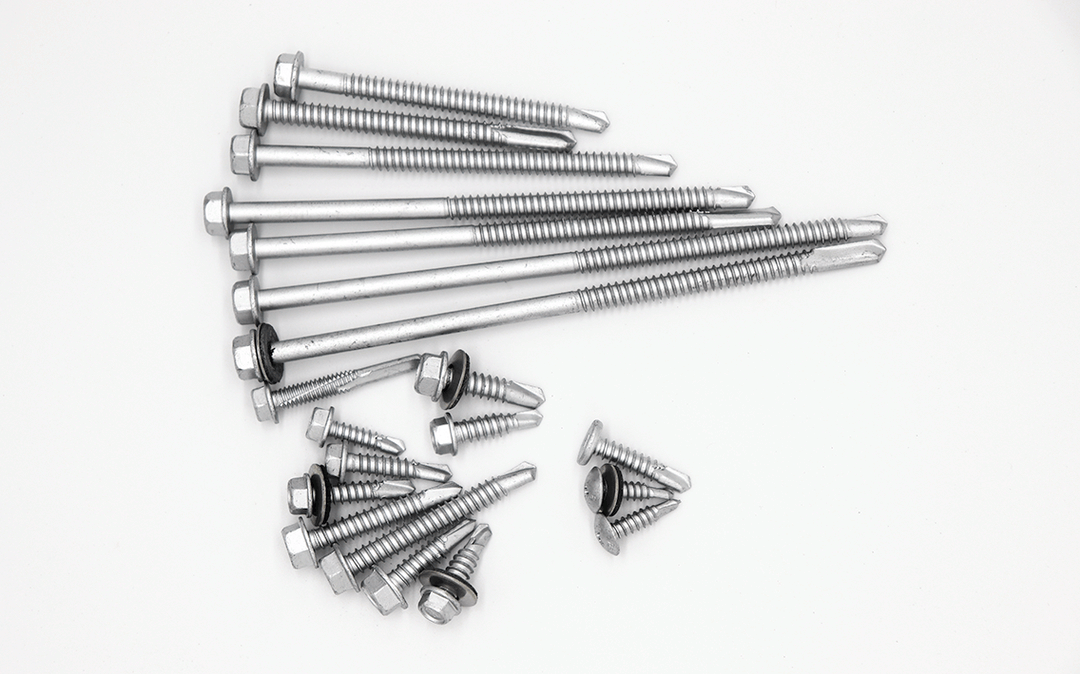

7. Self-Drilling Screws

For the quickest and most efficient installation of metal components, nothing beats self-drilling screws. Commonly referred to as TEK screws, these fasteners have a modified design that allows them to create their own pilot hole in one simple step - that eliminates the hassle of pre-drilling. With several head styles available including hex, pan and flat head shapes, this versatile screw is perfect for any application that requires speed and efficiency.

8. Euro Screws

Euro screws are specifically designed for use with European-style cabinet hinges and drawer slides. They have a flat head, a partial thread, and a special 5mm diameter shank, which allows for easy adjustment and secure attachment of hinges and slides to cabinet panels.

9. Lag Screws

Lag screws, also known as lag bolts, are heavy-duty fasteners used for connecting heavy lumber or other materials that require a strong connection. They have a hexagonal head and coarse threads, which provide excellent grip and holding power. Lag screws are typically used with a pre-drilled pilot hole and require a wrench or socket for installation.

10. Set Screws

Set screws are designed to secure one object within another, such as a gear on a shaft. They have no head, which allows them to be fully embedded into a pre-drilled hole. Set screws typically have a hexagonal socket and are tightened with an Allen wrench. They come in various thread types and point styles, such as cup, cone, and flat point, which allow for different levels of grip and holding power.

11. Grub Screws

Grub screws, also known as blind screws or headless screws, are similar to set screws since they are used to secure one object within another. They are typically used in applications where space is limited or where a protruding head would be undesirable. Grub screws have a flat or slightly-rounded point and are tightened with an Allen wrench.

12. Tamper-Resistant Screws

Tamper-resistant screws are designed to deter unauthorized access to protected areas or equipment. They have unique head designs, such as pin-in-torx or pin-in-hex, that require specialized tools for installation and removal. Tamper-resistant screws are commonly used in security, electronics, and other applications where vandalism or theft is a concern.

13. Metal Roofing Screws

Metal roofing screws are uniquely designed to securely fasten metal panels onto a building's underlying structure. They have an incredibly sharp self-piercing point, which eliminates the need for pre-drilling and prevents any damage to the sheet metal when attaching it. Metal roofing screws are designed to provide secure connections, durability, and weather resistance when used in metal roofing applications.

14. Self-Tapping Screws

Self-tapping screws can be used to join two pieces of material together. They are designed with a pointed tip and sharp threads that allow them to tap into the material as they are driven in, which creates their own mating thread. Self-tapping screws come in various sizes and materials, such as steel, stainless steel, and brass.

They are commonly used in applications such as sheet metal fabrication, woodworking projects, and automotive repair. Self-tapping screws provide an easy way to securely fasten two pieces of material together without the need for pre-drilling or tapping.

Fastener Systems Has the Right Screws for Every Project

Fastener Systems has the right fasteners for any job. Our selection is extensive, and includes everything from deck screws and lag screws to self-drilling and tamper-resistant types in different designs and materials. Plus, you'll find all the necessary tools, sealants, and other products needed to get your project done quickly.

Contact us today and request a catalog of our entire range of fasteners!